HOC8040-300

Reverse Osmosis Membrane For Sewage Treatment

Using a special membrane making process, it can reduce the adhesion and accumulation of organic matter, microorganisms and other pollutants on the membrane surface, and extend the cleaning cycle and service life of the membrane;

It has strong chemical stability and antioxidant properties;

It is suitable for various complex sewage water quality conditions, including high turbidity, high salinity, high COD, etc.

| Model | Stable desalination rate % | Minimum desalination rate % | Average water production (gpd) | Effective membrane area (ft²) | Inlet grid mil |

| FR8040-300 | 99.5 | 99.3 | 7,500 | 300 | 47 |

| Test conditions: 2,000ppm NaCl aqueous solution, Pressure 225psi (1.55MPa), Temperature 25℃, pH 7-8, Recovery rate 15%. | |||||

---Description

The flow rate of a single membrane element may be different, but the range of variation will not exceed +15%;

The stable desalination rate generally needs to be tested after 24-48 hours of continuous operation, depending on the inlet water quality and operating conditions.

Maximum operating pressure ································ 600psi(4.1Mpa)

Maximum inlet flow rate ································ 17m³/h

Free chlorine tolerance a ······························ <0.1ppm

Maximum pressure drop of a single membrane ···························· 15psi(0.1Mpa)

Maximum inlet temperature ································ 45℃

Maximum inlet water SDI15 ····························· 5

Continuous operation pH rangeb ······················ 2-11

Short-term cleaning pH range ························· 1-13

a. Under certain conditions, inlet water containing free chlorine and other oxidants can cause serious membrane damage, which is not covered by the product warranty due to oxidation damage;

b. When pH>10, the continuous operation temperature shall not exceed 35℃.

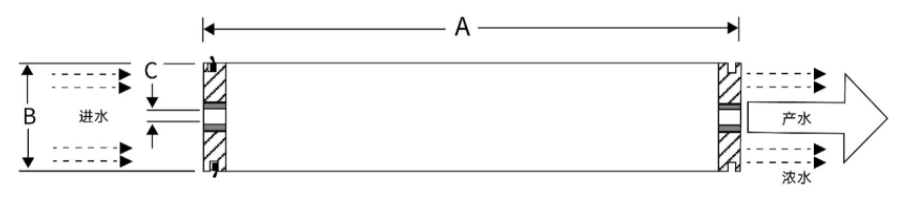

| Model | A | B | C | |||

| In. | mm | In. | mm | In. | mm | |

| FR8040-300 | 40.0 | 1,016 | 7.89 | 200 | 1.125 | 28.6 |

Customers' Recognition Of Us

Leave a Message

Your email address will not be published. Required fields are marked *